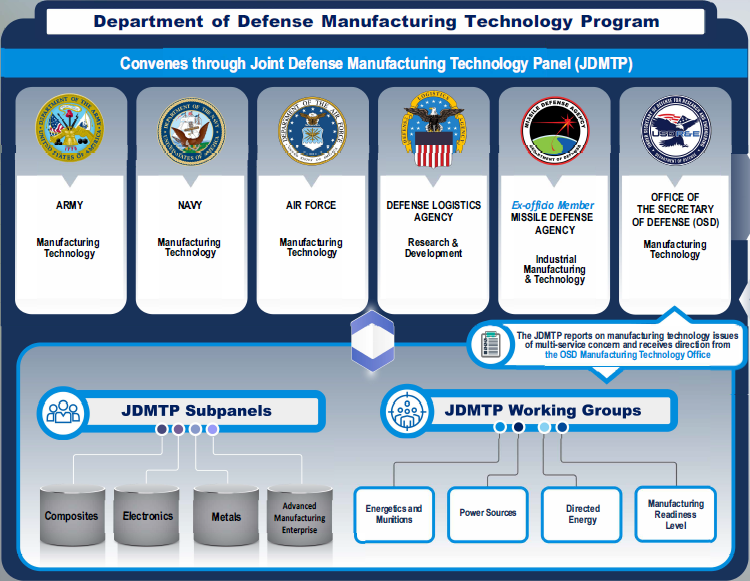

As the diagram above indicates, the primary mechanisms to support the Panel’s efforts are the JDMTP Subpanels:

Electronics,

Composites,

Metals, and

Advanced Manufacturing Enterprise. Where appropriate, the projects funded by all ManTech Programs are discussed, reviewed, and coordinated through the JDMTP and its Subpanels. Each of the four Subpanels consists of members from each of the ManTech Components as well as representatives of the larger JDMTP community, and industry. They meet regularly to review the projects within their technology portfolio, identify opportunities for collaboration, and provide input to the Panel on opportunities for future investment areas such as Joint Technology Pursuit Areas (JTPAs). The chairperson of each subpanel also meet regularly to coordinate on projects which cross traditional subpanel boundaries and enhance subpanel processes to increase efficiency and effectiveness in achieving the DoD ManTech mission.

Each subpanel has its own page with more information on focus areas, review processes, etc. Links are located on the menu to the right.

The JDMTP was originally chartered in 1999, but since has been given permanent authority under

10 U.S. Code § 4841. The JDMTP reports to and receives direction from the OSD ManTech Program on manufacturing technology issues of multi-service concern and application.